Nocolok Flux is a commonly used fluxing agent which is used for brazing aluminium components. It has an extremely low water solubility (0.2 % to 0.4 %), is non-hygroscopic and non-corrosive in nature and has an indefinite shelf life. Further, it is easy to apply, for example, it can be applied by spraying, dipping or flooding and the loading of the flux is controllable.

Why Brazing?

Brazing offers enhanced corrosion resistance, thus making the surface of the object suitable for different types of surface treatments, for example, painting. Brazing done using s suits complex product designs, continuous production and a variety of alloy selections. Hence, it is an ideal choice for brazing (the process of joining two or more metals); it is used in a number of industries.

These are:

-

Household Appliance Industry

Nocolok Flux is used to braze aluminium and stainless steel for manufacturing pots and pans. A mixture of filler metal powder and flux is often used between the aluminium base plate and the pot.

-

Electrical Appliance Industry

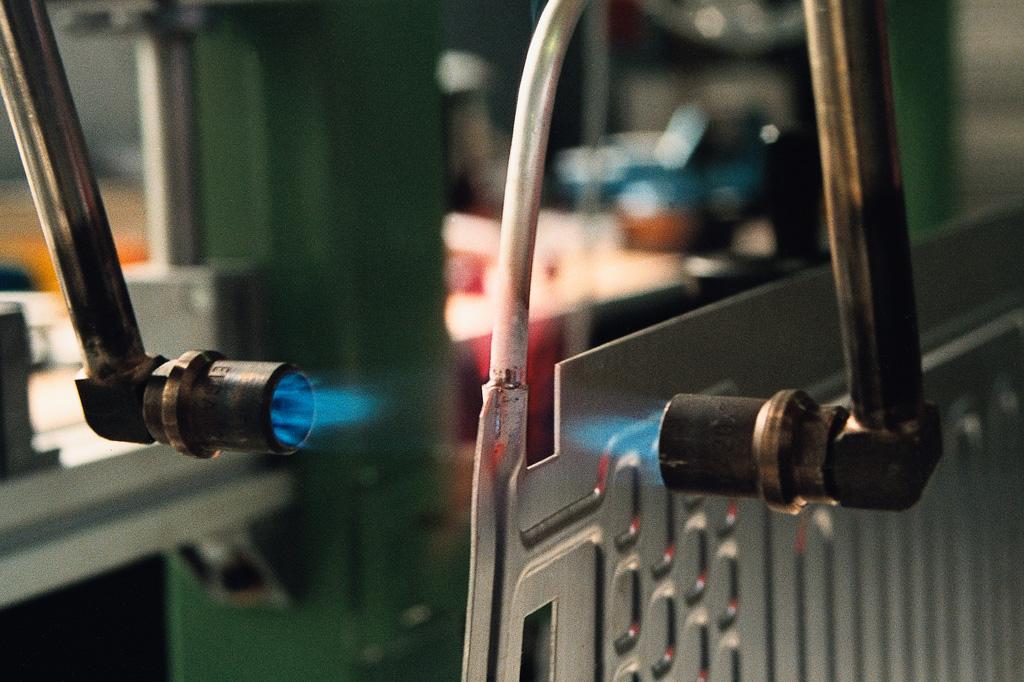

Conventional flame brazing technique is used to join aluminium tube to steel or stainless steel. A filler metal wire is placed into the joint before this process.

-

Automotive Industry

Most automobile parts manufacturers now use aluminium brazing process to manufacture automotive heat exchangers such as radiators, condensers, evaporators and heater cores. Hence, Nocolok Flux is used in this industry. The process involves joining components using a brazing alloy with a melting point lower than that of the other components.

-

Commercial and Residential Air-Condition Industry

Air-conditioner industry has been evolving rapidly and the role of Nocolok Flux deserves to be mentioned. It is used to manufacture brazed micro-channel heat exchangers. These are cost-effective solution which provides the following benefits:

- Minimizes the temperature between the air-flow

- Improves the heat transfer efficiency of heat exchangers

- Helps the refrigerants to reach phase-change temperatures quickly by increasing heat-transfer

- Lesser energy consumption

- Pressure drop reduction

- Lower weight

- Refrigerant charge reduction

- Reliable performance

- Noise reduction

- Recyclable

Refrigeration

Nocolok Flux is used for aluminium or copper flame brazing in the refrigeration industry. Generally, copper tubes are brazed to aluminium roll-bond tubes or panels.

Are there different types of Nocolok Flux?

Yes, there are. Ask your seller to decide on the type of flux you should choose depending upon the industry-specific usage. Some of the types are:

- NOCOLOK® Flux Drystatic

- NOCOLOK® Sil Flux (extra fine grade)

- NOCOLOK® Sil Flux (fine grade)

- NOCOLOK® CB Flux

- NOCOLOK® Cs Flux

- NOCOLOK® Zn Flux

- NOCOLOK® Li Flux

- NOCOLOK® Li Flux Drystatic

- NOCOLOK® Binder (water-based)

- NOCOLOK® Flux Plus Binder Mixture

- NOCOLOK® System Binder (water-based)

- NOCOLOK® Sil Flux (extra fine grade) Plus Binder Mixture

- NOCOLOK® System Binder (water-based)

- NOCOLOK® Thickener (water soluble)

- NOCOLOK® Precoating (water soluble)

- NOCOLOK® Braze Paste x43-7