EMI or RFI shielding gaskets provide an electrically conductive seal for any electronic device openings. They are used in electronic enclosures to protect other devices from electromagnetic interference. Elastomer products or materials are known for their flexibility, damping, resilience and their ability to elongate. All of these unique properties make them a perfect material for seals, gaskets, isolators, and the likes. They are made of different kinds of polymers and are blended with various kinds of fillers. These conductive materials let you use the same gaskets for EMI/RFI shielding, and for environmental seals. EMI gaskets are widely used by the electronic or electrical industry in order to comply with the EMC or EMI regulations. Read on to learn about the benefits and different types of EMI/RFI shielding gaskets.

The Benefits

There are manifold benefits of conductive elastomer sealing gaskets. They are:

-

Ideal for EMI shielding. You can even use them as environmental gaskets, enabling maximum use of space.

-

Provides outstanding shielding efficiency

-

Elastomer shielding gaskets are available in varied shapes and profiles to meet your precise shielding requirements.

-

Available with varied mounting methods

-

Low-cost materials are available

-

You can achieve low compression forces when using hollow gaskets

Conductive Silicone Rubber EMI Gaskets: The greatest benefit of EMI sealing gaskets made from conductive silicone elastomers is EMI protection and environmental sealing over a wide temperature range. This product is typically made from silicone or fluorosilicone rubber and comes embedded with silver plated copper particles, aluminum fillers, nickel-graphite fillers, silver plated glass beads and even conductive carbon. Most of the EMI shielding gaskets comply with Mil-G-83528B properties. They are cast into sheets from 12 inches by 12 inches to 10 inches by 15 inches in size and .010 inches to .125 inches in thickness. For the final configuration, these materials are die-cut to perfection.

EMI Shielded Molded Gaskets: When it comes to molding gaskets, they let the designer integrate sealing ribs or any other performance boosting features to maximize EMI/RFI shielding properties as well as environmental sealing.

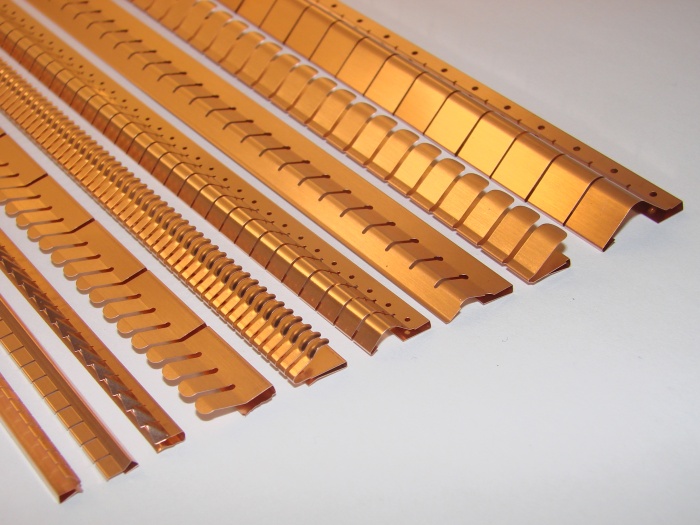

EMI or RFI Knitted Wire Gasket: EMI/RFI rigid-frame shielding gaskets are one of the most common shielding products. You’ll find them in a number of cross sections to meet diverse shielding application requirements. You can choose from circular, rectangular, double round with fin or circular with fin based on the kind of electronic equipment or enclosure to be protected from electromagnetic interference.

Rigid-frame gaskets come with an aluminum extrusion and custom-made jaw. When you close it, the jaw folds the fin of this gasket, resulting in a firm construction with the knit wire EMI gasket held tightly in its place. The extrusion when put together in a frame and the heliarc soldered and the corners of the extrusion mitered, gives you an EMI gasket that can be installed with the help of flat-head screws. This rigid-frame gasket is ideal for access panels and cabinet doors that are often opened or closed. These gaskets are extremely durable and assure maximum protection against electromagnetic interference. If you need a moisture seal, an elastomer strip can be tied to the rim of the extrusion, opposite of the gasket.

For added protection against EMI or RFI interference, you can opt for products with a two-sided structure. These gaskets are perfect for large doors where managing the mating surface joint jaggedness is costly and challenging. You’ll find an array of these shielding gaskets available in the market. The standard ones are tin-plated ferrous or ones made from Monel. Besides, there are other material combinations like silver-plated brass, aluminum, tungsten, gold-plated copper, nickel, silver, or any other material that can be designed to produce special EMI shielding products.

Choose quality elastomer products for effective protection against electromagnetic interference and environmental sealing. Talk to the supplier for cost-effective solutions to your EMI/RFI shielding needs.