Oscillating movements in machines need to be controlled and executed specifically to prevent damage. Slew bearing rings are to be used to mediate these oscillating movements and ensure that the machine runs smoothly.

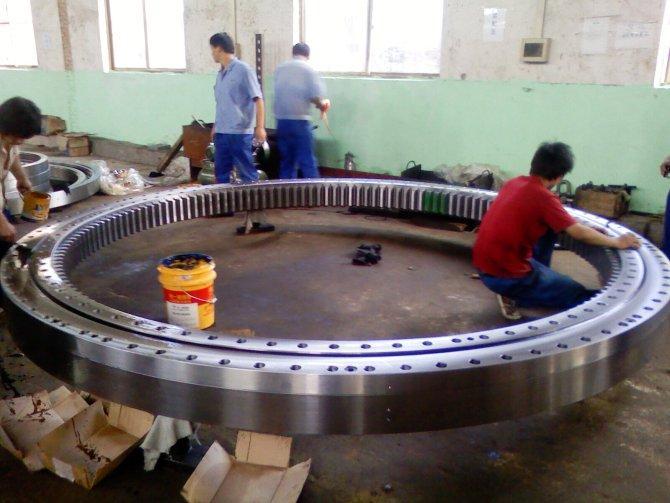

Slew bearing rings are usually in two parts, one inner and one outer ring, with a gear incorporated into one of the two rings. These components in combination generally ensure that the oscillating elements perform to the maximum of their ability.

Slew bearing rings are generally specifically designed with synthetic rubber seals, which prevent any damage from foreign matter and also ensure that there is no wastage or leakage of grease. With various advantages added by using slew bearing rings, it is also important to remember to make the selection of the slew bearings carefully.

The following things need to be kept in mind in order to use your rings for slew bearing correctly:

1. How much force is to be applied to the gear supporting the rings?

Take stock of all forces that might be applied to the slew bearing rings. This would not only include the working forces, but also the forces to be applied when the equipment is at rest. Sometimes, for example, larger structures might be faced with unprecedented force due to wind.

2. Factor in overload situations

Situations where there is over load in the machine needs to be factored in before making the selection. This way, there would be no unforeseen damage.

3. Weight of the structures supported by the bearing

The weight of all the structures that the bearing is supporting needs to be noted before selecting the apt slewing ring for the job.

4. Maximum possible loads need to be factored in

The maximum possible loads that the bearing would support in different combinations need to be factored in before making the choice.

5. The arrangement of weights on the bearing

The mounting arrangement of the load and installation and maintenance of the bearing need to be factored in at the time of selection of slewing rings.

6. Know the product

Before purchasing any such product, it is absolutely essential to know it completely. The technical guide to the product use needs to be gone over carefully for the same.

7. Make a preliminary selection before going in for the final

This helps in the elimination process, and the arrival at the right choice of a ring for slew bearing.

8. Gear rating check

When applicable, the gear rating of the selected ring for slew bearing needs to be checked for complete compatibility of use and satisfaction in purchase.

9. Finally, compatibility check

The last test is that of compatibility between the bolts, plates and joint arrangements. Once the compatibility of installation has been approved of and considered apt for use that is when one must purchase the slewing ring for optimum results.