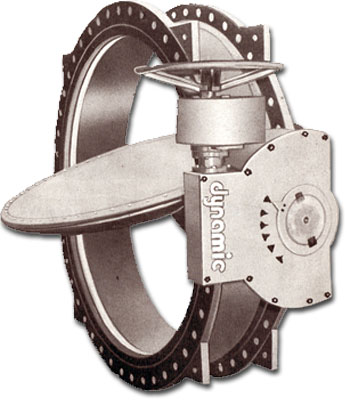

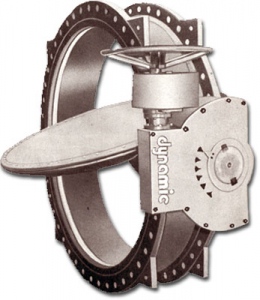

A butterfly valve comes from a family of valves known as quarter turns. The specific term refers to the metal disc that is mounted onto a rod. When closed, the disc turns on the rod in a way so that the passageway is completely blocked. The disc will rotate a quarter turn when the valve is open so that there is unrestricted passage. The outside of the valve affects the actual position of the disc.

Much like anything mechanical, there exist several kinds of butterfly valves that all handle different usage or pressures. For instance, there is the resilient butterfly valve that uses rubber and comes with a rather low pressure rating. High performance valves offset the position of the disc in some way but comes with a slightly higher pressure system and can have a tendency to wear and tear. The highest pressure rating comes with the tricentric valve that uses a metal seat to improve its pressure durability.

Even if most people do not know it, most people use butterfly valves in some part of their lives. One common example is a car carburetor. In such a car, the gas pedal will operate a valve that in turn operates the air intake of the engine. By pressing down the pedal straight to the floor, the valve opens entirely so the air can enter the carburetor, which then lets it with the gas pass through the poppet valves into the combustion chambers for the engine to ignite it.

Valves do not just remain fully open or fully closed; they only open slightly when a car is idle, letting the air pass enough just to maintain that speed. The harder the pedal is pressed, the more it opens to let more and more air in.

The stem is another important part to a steam setup as it is in the middle of the valve and attached to the acutator, optimizing the disc positioning in order to properly allow materials to flow and stop. There are both one and two piece models available for stems, and the exact type used depends on the size and specific use of the valve. Common construction materials include stainless steel and carbon steel.

Prior to purchasing a valve, it is important to consider the price of the valve, whether it has a removable or permanent seat, how easy it is to install and whether it is the right kind of valve for the materials and environment involved.

Cheaper valves can have seats molded in the bodies which makes it impossible to ever repair it. On the other hand, more expensive valves have removable seats that can easily be replaced. The added initial expense will eventually pay for itself over time.

It is also important to avoid damage and thus need of replacement by knowing the correct operation of the disc. Having the right disc determines how materials flow in the line. Taking the proper precaution is important when deciding the right material and shape of disc because it is involved with the flow. In addition, some discs have designs that allow for different patterns of flow.

The solenoid valve which is often used in fluidics allows different substances, such as liquid, gas, steam or air, to flow through pipes and tubes. In addition, some solenoid valves can even pass some dry materials along with wet ones. Getting a solenoid valve is an excellent way to ensure one receives an inexpensive valve with top notch performance to be used with different kinds of liquids and gases.

A butterfly valve is durable, especially with manual types, and using it guarantees that the method of shut off is dependable and reliable, especially when the body is made from durable materials as well.